Where Gigabyte Motherboards Are Made

Are you planning to pick up a Gigabyte GA-P45-DQ6? Over the course of this article, we'll show you where it was made as Gigabyte invited bit-tech to one of its Taiwanese factories, allowing us to roam around its facilities.The Nan-Ping factory is about an hour out from Taipei City where Computex was happening in full swing; it's one of four manufacturing plants that Gigabyte owns. The second is located in Ping-Jen in Taiwan and the remaining two factories are in China: Ning-Bo (just south of Shanghai) and Dong-Guan further south still. Nan-Ping isn't your typical expansive factory – it's almost as tall as it is wide, with eight huge floors offering 45,000 square metres of space for 1,200 employees.

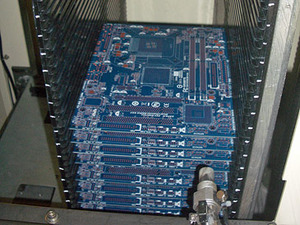

The factory features eleven SMT lines (seventh Floor) providing 400,000 motherboards, 300,000 graphics cards and 5,000 server products a month. There are also six lines of DIP and Testing (fourth and fifth floors) and four lines of packing all those motherboard, VGA and server products up on the second floor.

There are also two lines of whole system assembly for its OEM and retail business on the third floor and two lines for its mobile assembly unit (20,000 units per month) for Asia on the sixth floor.

The factory also has attained five ISO standards and it is 14,000 and 9,001, OHSAS 18001, IECQ QC 080000 and TL 9000 certified.

Your Gigabyte motherboards are belong to Nan-Ping

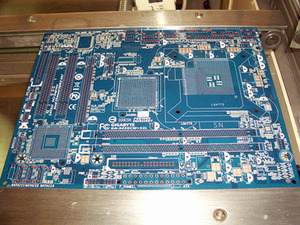

Manufacturing starts out in the SMT area, where the PCBs Gigabyte originally outsources are subjected to X-ray checking and internal QC before being solder pasted up and then wheeled down to initial high speed component placement. This is where all the little surface mount parts like resistors and ceramic capacitors get fired into place by a multi-headed gun that looks at the board layout and puts the piece into place. The camera is tailored to Gigabyte's blue PCB dye so it works particularly fast because usually these cameras work best with traditional green or yellow coloured PCBs.

Before we were allowed in the SMT area we had to be mostly dust free – the "air showers" were... an experience, to say the least.

Before we were allowed in the SMT area we had to be mostly dust free – the "air showers" were... an experience, to say the least.After this process is complete, the larger components are placed by a "multi-function placement machine". This step includes placing parts like chipsets and larger ICs that are traditionally stuck to a reel. The PCB is then run through a reflow soldering stage and is then inspected and tested for basic errors.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.